Production process

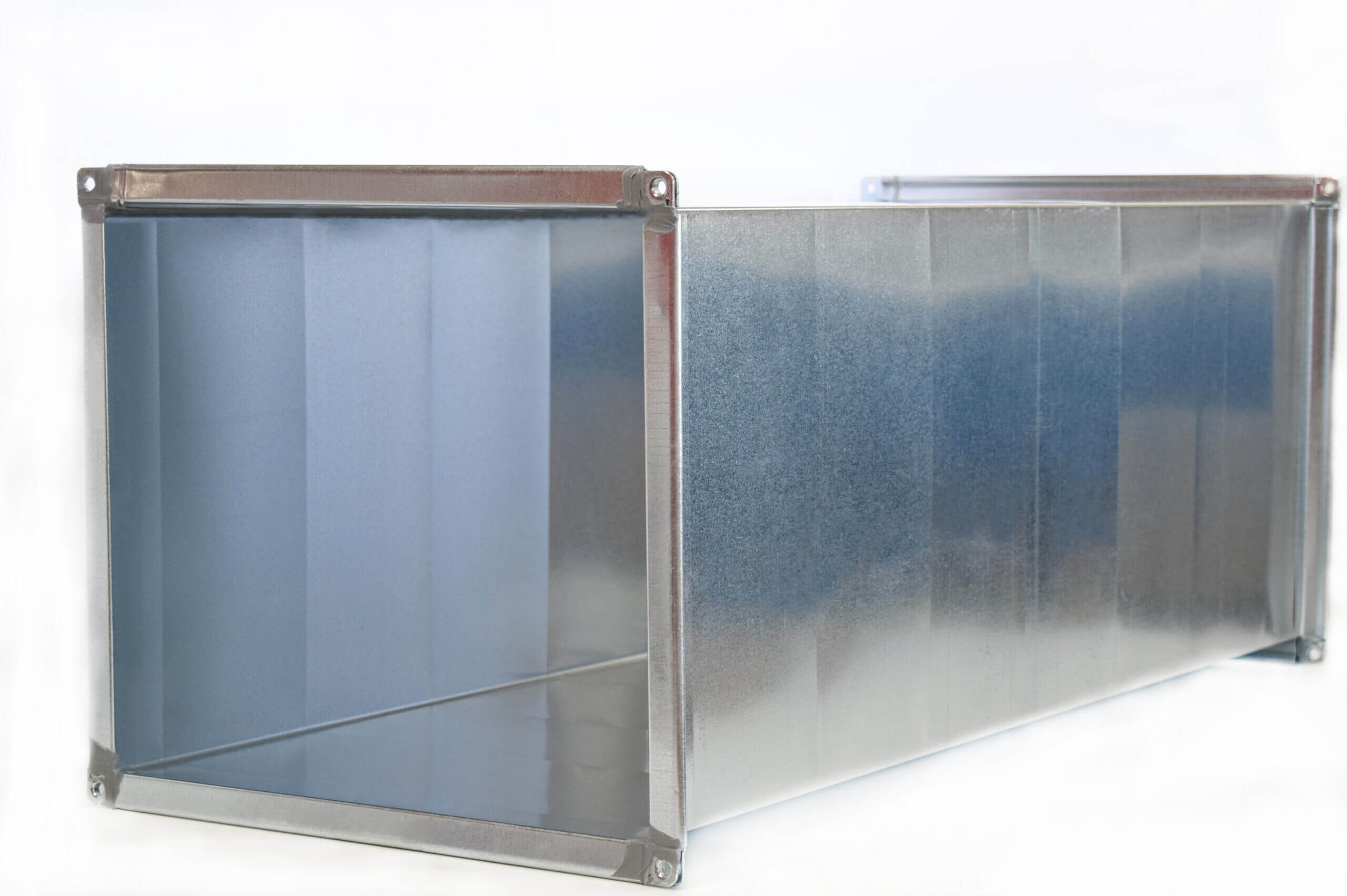

At “PSYKTIKI-THERMIKI” the production process is carried out under the strictest specifications with modern equipment and new methods.

The company is currently equipped with the following technical infrastructure:

• Plasma pantograph for sheet metal cutting with cnc cutting table.

• Automatic production line for straight air conditioning and ventilation

• Manual system for creating flanges in air ducts of rectangular cross section.

• Press for making a 7mm flange.

• Stitch welder type semi-automatic circular air duct welding machine.

• Forklift.

• Two 2-meter stretches.

• Two cutting scissors.

• Five edge shaping rollers.

• Circular component mounter.

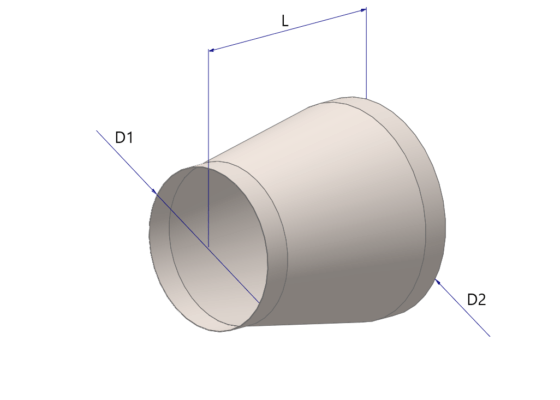

• Machine for making circular winding air ducts.

Ελληνικά

Ελληνικά